Description

Customized megnetic inductance defective crack size automatic machine vision inspection detection machine Chinese manufacturer designed

Product Description:

Equipment type | SP-600 series |

Machine characteristics | dedicated die-cutting or film-carrying coil testing platform |

Main Functions | Detecting Leakage, Offset, Angle, Position Offset, Burr |

Scope of application | Suitable for all types of die cutting, pot chip, label size, printing character coil width less than 150 mm, wide range customizable |

Detection accuracy | the highest accuracy can reach 0.25mm |

Detection efficiency | up to 300-1000CM/min |

Our Company

Since its establishment 16 years ago, Shenzhen Sipotek Technology Co., Ltd. has been committed to the research, development and manufacturing of image technology and machine vision, with more than 70 senior R&D personnel of machine vision system and industrial automation engineers. The company’s key technical personnel are mainly from huawei, byd, foxconn and other first-class manufacturing enterprises, with many years of mature experience in software design, visual and image comparison technology, industrial automation and other aspects.

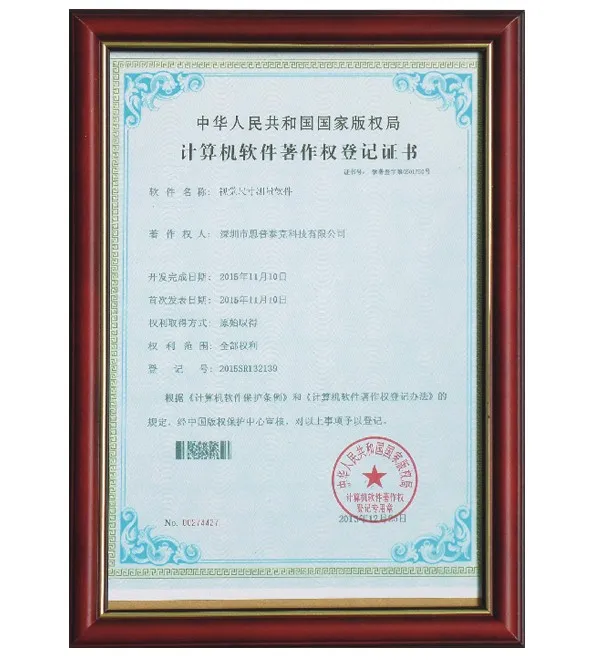

In 2014, the company established a software R&D center in Shanghai, focusing on 3D machine vision systems and 3D modeling application software, leading the new benchmark in vision systems. After years of innovation and research, the company won the title of “National High-tech Enterprise” in 2013, and has a number of invention and innovation patents. The company has been strongly supported by the Shenzhen Government and the Innovation Committee.

The machine vision system developed and manufactured by our company has been well applied by many internationally renowned companies such as Midea, Foxconn, Chery Automobile and BYD, etc. With the arrival of The 4TH industrial revolution, our team will provide better system products and services to enable customers to enjoy better scientific and technological achievements.

For Product Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: +86-18617182707

Website: https://www.topvision.net

1.What’s the minimum order quantity (MOQ)?

– 1 machine, small batch and large volumes are acceptable.

2.When can I get the quotation?

– We usually respond within 24 hours on working days receiving your quotation. Then we will discuss the inspection details and requirements as much as possible to design your inspection solutions. After receiving samples for testing and evaluating, a solution will be born and will be forwarded to you with quotation within one week.

3.Which is the safe payment method to trade?

– We accept T/T, LC, Paypal, Trade Assurance and Secure payment on Alibaba platform.

4.How long will it take to produce the machine?

– For standard machine, it will be 15 days for manufacturing.

– For non-standard machine, it will be negotiated customized according to your requirements.

5.What’s the shipping method of Sipotek?

– We are able to ship worldwide where Ocean shipping or Air shipping can reach.

– Machines will be packed safely and protectively to ensure you will receive a brand new one.

6.How do you ensure quality control?

– Sipotek is a professional machine vision inspection supplier with 16 years experience of research and develop in this field. We ensure 100% brand new machine production. Our machine is stable and reliable to help you increase quality efficiency.

7.What’s the warranty and after-sales service?

– Sipotek warrants all the machines made by Sipotek under normal use of a period of A YEAR after the date of the original purchased. Sipotek will train buyers how to install the machine and how to use the machine for free. We also provide a life-time technical support or software upgrade service.